Decoding The Brass Gas Valve Industry: Manufacturers' Perspectives

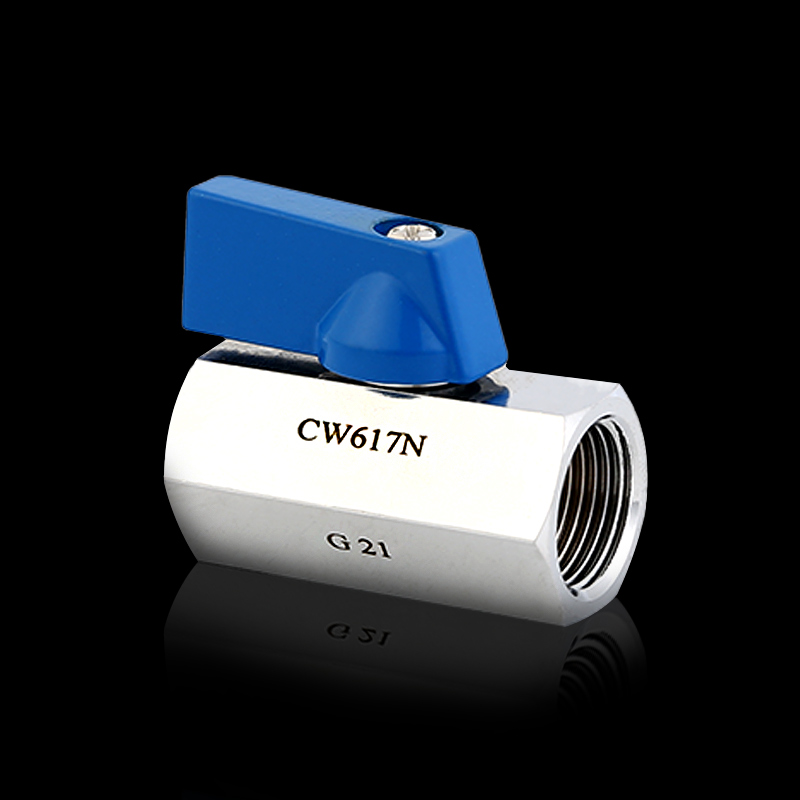

Design High Quality Brass Gasoline Shut Off Valve Manufacturers

In the realm of gas valves, brass remains a stalwart material renowned for its durability and reliability. Manufacturers of brass gas valves play a crucial role in shaping the industry landscape, offering diverse solutions to meet the needs of various applications. In this article, we delve deep into the realm of brass gas valve manufacturers, exploring their perspectives, practices, and contributions to the industry.

Brass gas valve manufacturers are instrumental in supplying a wide array of valves catering to residential, commercial, and industrial sectors. These manufacturers specialize in crafting valves that withstand high-pressure environments, ensuring safety and efficiency in gas distribution systems. With a keen focus on quality and innovation, brass gas valve manufacturers continually strive to enhance their products to meet evolving market demands.

The production process employed by brass gas valve manufacturers involves meticulous attention to detail and adherence to stringent quality standards. From sourcing high-grade brass materials to precision machining and assembly, every step is carefully orchestrated to deliver predominant products. By leveraging advanced manufacturing technologies, brass gas valve manufacturers optimize efficiency and maintain consistency in product quality.

One of the key distinguishing factors among brass gas valve manufacturers is their commitment to customization. Recognizing that different applications have unique requirements, these manufacturers offer a range of customization options to tailor valves to specific needs. Whether it's adjusting valve dimensions, modifying flow characteristics, or incorporating specialized features, manufacturers collaborate closely with customers to deliver bespoke solutions.

The competitive landscape of brass gas valve manufacturers is characterized by a diverse range of players, each bringing its own strengths and capabilities to the table. While some manufacturers focus on mass production to cater to broad market segments, others prioritize niche markets with specialized requirements. Despite differences in approach, all brass gas valve manufacturers share a common goal of delivering reliable and cost-effective solutions to their customers.

In addition to product innovation, brass gas valve manufacturers place a strong emphasis on customer service and support. From technical assistance during product selection to after-sales service and maintenance, manufacturers strive to foster long-term partnerships with their customers. By providing comprehensive support throughout the product lifecycle, manufacturers enhance customer satisfaction and loyalty.

The role of brass gas valve manufacturers extends beyond product supply to industry advocacy and collaboration. Manufacturers actively participate in standards development initiatives and regulatory compliance efforts to ensure the safety and reliability of gas valve systems. Through industry associations and partnerships, manufacturers contribute expertise and resources to address common challenges and drive collective progress.

Despite facing challenges such as fluctuating raw material costs and market volatility, brass gas valve manufacturers remain resilient and adaptable. By leveraging their technical expertise, market insights, and collaborative networks, manufacturers navigate uncertainties and seize opportunities for growth. Continuous investment in research and development enables manufacturers to stay ahead of emerging trends and maintain their competitive edge.

In conclusion, brass gas valve manufacturers play a pivotal role in shaping the dynamics of the gas valve industry. With their commitment to quality, innovation, and customer satisfaction, manufacturers drive the evolution of gas valve technology and contribute to the advancement of gas distribution systems. As the demand for efficient and reliable gas valves continues to grow, manufacturers will continue to play a vital role in meeting the needs of diverse applications and industries.

NEXT:Surveying Brass Gas Valve Manufacturers: Range And Reliability

Product Series

Contact Us

Feel Like Talking

+ 86-576-89902377

+ 86-576-89902379

Contact Email

tdb@tdbvalve.com

Address

Chumen LongWang Industrial Zone, Yuhuan City, Zhejiang, China, 317605

English

English 한국어

한국어 Español

Español 中文简体

中文简体