Meeting Industry Standards: The Commitment Of Brass Gas Valve Manufacturers

Design High Quality Brass Gas Valve For Gas Manufacturers Maker

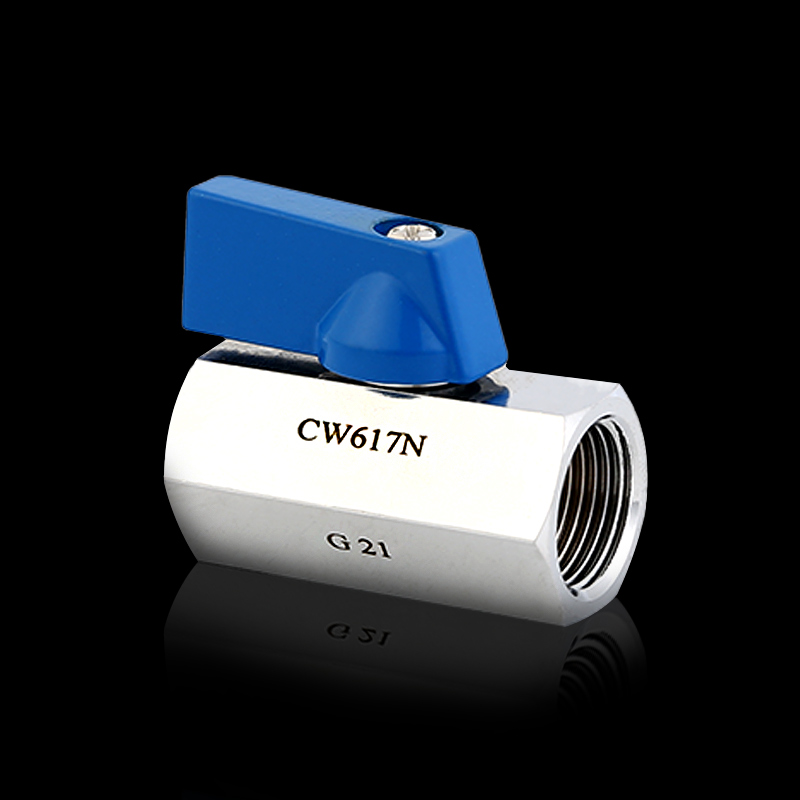

Brass gas valves are essential components in gas supply systems, providing control and regulation of gas flow in residential, commercial, and industrial settings. Behind the scenes, brass gas valve manufacturers play a crucial role in ensuring the safety, reliability, and performance of these valves. In this article, we will delve into the commitment of brass gas valve manufacturers to meeting industry standards and delivering high-quality products.

1. Understanding Industry Regulations: Brass gas valve manufacturers operate in a highly regulated industry governed by strict standards and regulations to ensure safety and compliance. From material sourcing to production processes and product testing, manufacturers adhere to industry standards set by organizations such as ASTM International, the American National Standards Institute (ANSI), and the International Organization for Standardization (ISO). By staying abreast of regulatory requirements, manufacturers ensure that their brass gas valves meet or exceed industry standards for quality and safety.

2. Quality Materials Selection: The foundation of a reliable brass gas valve lies in the quality of materials used in its construction. Brass gas valve manufacturers carefully select materials known for their durability, corrosion resistance, and compatibility with various gases. High-quality brass alloys, such as lead-free brass, are commonly used for their predominant strength and chemical resistance, ensuring long-term performance and reliability of the valves.

3. Precision Manufacturing Processes: Brass gas valve manufacturing involves precision machining and assembly processes to ensure the proper functioning of the valves. Manufacturers employ advanced machining techniques, such as CNC (Computer Numerical Control) machining, to achieve tight tolerances and precise dimensions in valve components. Additionally, automated assembly systems ensure consistency and accuracy in valve assembly, fewer the risk of defects and ensuring uniform quality across batches.

4. Stringent Quality Control Measures: Brass gas valve manufacturers implement stringent quality control measures at every stage of the manufacturing process to detect and address any deviations from specifications. Incoming raw materials undergo rigorous inspection to verify their quality and conformity to standards. During production, in-process inspections and testing procedures are conducted to monitor quality and identify any defects or non-conformities. Final inspection and testing ensure that each brass gas valve meets performance, reliability, and safety requirements before being shipped to customers.

5. Product Testing and Certification: Prior to market release, brass gas valves undergo comprehensive testing to validate their performance, reliability, and safety. Manufacturers conduct a battery of tests, including pressure testing, leakage testing, flow testing, and endurance testing, to evaluate the valves under various operating conditions. Additionally, valves may undergo certification by independent testing laboratories or certification bodies to verify compliance with industry standards and regulatory requirements. Certifications such as UL (Underwriters Laboratories) and CSA (Canadian Standards Association) provide assurance of product quality and safety to customers and regulatory authorities.

6. Continuous Improvement Initiatives: Brass gas valve manufacturers are committed to continuous improvement initiatives aimed at enhancing product quality, efficiency, and customer satisfaction. Through feedback mechanisms, customer surveys, and internal audits, manufacturers gather insights into areas for improvement and implement corrective actions to address any issues or opportunities for enhancement. Continuous training and development programs ensure that employees are equipped with the knowledge and skills necessary to uphold quality standards and drive ongoing improvement efforts.

7. Customer-Centric Approach: Brass gas valve manufacturers prioritize customer satisfaction by understanding and meeting customer needs and expectations. Manufacturers work closely with customers to provide customized solutions tailored to their specific requirements, whether it's custom valve configurations, packaging options, or delivery schedules. Responsive customer support teams are available to address inquiries, provide technical assistance, and resolve any issues or concerns promptly. By fostering strong relationships with customers, manufacturers build trust and loyalty, ensuring long-term partnerships and mutual success.

8. Environmental Responsibility: In addition to meeting industry standards for product quality and safety, brass gas valve manufacturers are increasingly focused on environmental responsibility and sustainability. Manufacturers implement eco-friendly practices such as waste reduction, recycling, and energy efficiency initiatives to smaller their environmental footprint and promote sustainable manufacturing practices. By adopting sustainable practices, manufacturers contribute to the preservation of natural resources and the protection of the environment for future generations.

In conclusion, the commitment of brass gas valve manufacturers to meeting industry standards is paramount to ensuring the safety, reliability, and performance of brass gas valves. Through adherence to strict quality control measures, precision manufacturing processes, comprehensive product testing, and continuous improvement initiatives, manufacturers uphold the high standards of quality and safety in their products. By prioritizing customer satisfaction and environmental responsibility, manufacturers demonstrate their dedication to excellence and sustainability in the brass gas valve industry.

NEXT:Reliability Matters: Ensuring Quality With Brass Gas Valve Manufacturers

Product Series

Contact Us

Feel Like Talking

+ 86-576-89902377

+ 86-576-89902379

Contact Email

tdb@tdbvalve.com

Address

Chumen LongWang Industrial Zone, Yuhuan City, Zhejiang, China, 317605

English

English 한국어

한국어 Español

Español 中文简体

中文简体